Smart Packaging for Cost Efficiency

In the competitive world of B2B packaging, businesses are constantly searching for materials that balance cost, quality, and sustainability. MDF (Medium Density Fiberboard) wooden boxes are emerging as a practical choice for bulk packaging projects — combining strength, style, and affordability.

Unlike solid wood boxes, MDF wooden boxes maintain an excellent appearance at a fraction of the cost, making them perfect for companies managing large-scale distribution, exports, or retail supply chains.

🧱 What Makes MDF Wooden Boxes Cost-Effective?

MDF wooden boxes are manufactured using engineered wood fibers bonded under high pressure. This process allows factories to reduce material waste while maintaining the look and feel of real wood.

Here’s why they’re a top pick for cost-conscious buyers:

✅ Lower Material Cost: MDF panels are more affordable than solid hardwood, reducing total packaging expenses.

✅ Stable Quality: Uniform texture and density minimize product defects.

✅ Customization Flexibility: MDF accepts painting, veneer, and UV printing easily, ensuring brand consistency.

✅ Mass Production Efficiency: Sheets are standardized for bulk manufacturing, improving lead time and cost per unit.

📦 Ideal for Bulk Orders and Export Packaging

When packaging thousands of products, consistency and space optimization matter as much as durability. MDF wooden boxes are lightweight yet strong, helping companies save on both shipping and warehousing costs.

For exporters, MDF boxes can be tailored to meet customs and transport regulations while offering a refined, professional appearance for global markets. Many Wooden Boxes Wholesale suppliers now prioritize MDF because of its scalability and environmental advantages.

🌍 Sustainability and Eco Advantages

Another cost benefit comes from sustainability. MDF wooden boxes are made from recycled wood fibers — meaning they’re eco-friendly and compliant with most green packaging standards.

Choosing this material allows your brand to reduce raw timber consumption while supporting circular economy principles.

Moreover, partnering with an experienced MDF Wooden Boxes Manufacturer ensures that waste is minimized during production, helping you achieve lower carbon footprint targets for B2B packaging projects.

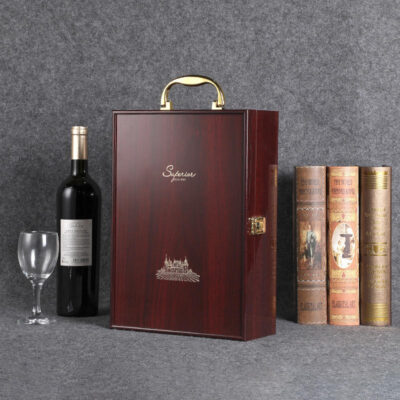

🏷️ Customization Options to Enhance Brand Value

Even with a lower base cost, MDF boxes allow for premium finishing touches, including:

-

🎨 Surface treatments (matte/gloss lamination, paint, or varnish)

-

🔲 Engraved or printed logos

-

🧲 Magnetic closures or ribbon ties

-

📐 Custom size configurations for retail packaging

These features allow you to transform simple MDF packaging into high-end custom wooden boxes, appealing to clients across multiple industries. For brands that want a balance between cost and design flexibility, working with a professional Custom Wooden Boxes Manufacturer is key.

💬 Conclusion: Affordable Quality for Growing Brands

MDF wooden boxes represent the future of cost-efficient and sustainable packaging. By reducing material waste, improving production speed, and allowing premium customization, they deliver both affordability and brand impact.

Whether you’re a retailer, wholesaler, or importer, switching to MDF wooden boxes is a smart move to optimize your packaging budget while maintaining a high-quality presentation that customers will remember.